Innovations in Voice Technology for the Warehouse

Do you remember when touch screens were just the worst? It wasn’t very long ago when touch screens required jamming your fingers on a screen over and over again without the screen registering anything. Chances were your configuration was off anyway so even if the screen caught your touch, it sent you to a different button than intended.

Do you remember when touch screens were just the worst? It wasn’t very long ago when touch screens required jamming your fingers on a screen over and over again without the screen registering anything. Chances were your configuration was off anyway so even if the screen caught your touch, it sent you to a different button than intended.

In 15 short years, so much has changed in the world of touch screens. I recently witnessed a two-year-old child happily playing with an iPad with no help needed, swiping and clicking as if it were second nature to her. I wonder if that would be possible with the touch screens of the past.

It got me thinking about other technologies that were introduced with the goal of making people’s lives easier, but actually caused more trouble than they were worth. One of these is voice technology.

Drawbacks of Traditional Voice Applications

Voice as a technology in supply chains has been around for a few decades. It was introduced to improve speed and accuracy to warehouse picking. Like the early touch screens, voice had some pretty serious drawbacks. From the high cost of implementation to the complexity of deployment, the adoption of voice in warehouse picking was limited. Some of these historical drawbacks include:

- Voice-dedicated hardware: Traditional voice apps require a separate, proprietary computer that house the speech-to-text and text-to-speech processor.

- Middleware or system interfaces: Voice apps of the past require middleware between a warehouse management system and using Terminal Emulation or web apps on their mobile computers to interact with that system.

- Host system modifications: Adding voice to the mobile app often required changes to the host system in order to properly communicate data.

- Post-deployment host modifications: Once workers are voice-enabled and realizing productivity gains, traditional voice vendors will require that you contract them to make changes to your host system so they can ensure their app isn’t adversely affected.

It’s easy to see that these drawbacks made voice a drain on time and money in the warehouse.

Speakeasy: A Better Approach to Voice

In the same way that Apple innovated touch screens to turn them from a hassle to a winning product, Ivanti decided it was time for a fresh approach to voice-enabled solutions in the warehouse. That’s where Speakeasy, powered by Wavelink, comes in.

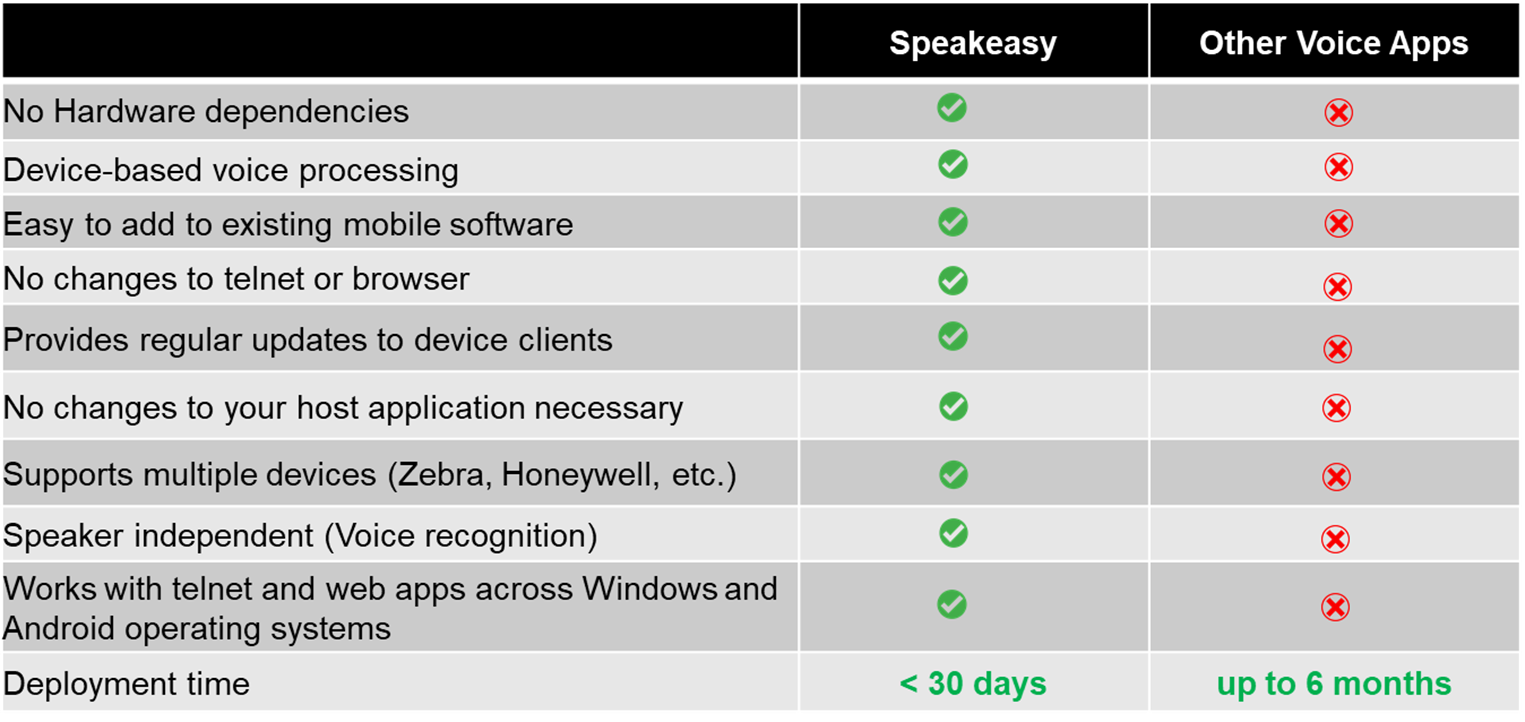

Speakeasy set out to do what voice was originally intended to do—improve speed and accuracy in warehouse picking. Speakeasy eliminates complexity and extra costs that still frequently come up with other voice app vendors. In the table below, it’s easy to see the benefits of Speakeasy.

With Speakeasy, you’re looking at no middleware—it works with any WMS and you don’t need to purchase proprietary voice hardware. This means that if you want to make a change to your WMS, you don’t need to worry about additional charges from your voice provider. Gist, the main supply chain provider for Starbucks, uses Speakeasy in their warehouse. “Speakeasy just sits on top of the telnet client that is installed on all of our devices to connect to our WMS, so we did not need to change anything,” Marcus Jeffery, Business IM Manager, Major Accounts at Gist said.

Implementing Speakeasy in your warehouse couldn’t be easier. Trials and pilots often implement the solution in less than a week, with full implementations being completed in 30 days or less. “The implementation of Speakeasy happened in a week,” Danny Sanders, Director of Distribution at Toshiba Americas Business Solutions said.

Speakeasy isn’t just fast to implement—it’s also quick and simple to train staff to use. In a world with high employee turnover, this is crucial. Ivanti customer Dorman Products implemented Speakeasy, which took them from several hours of training down to only 15 minutes to start using their picking system. Another Ivanti customer, J. J. Keller, was also impressed by training times and ease of use. “I love the voice system. You only handle a package once and it’s out the door. It’s so easy, it’s like brushing your teeth. Instead of clicking 10 times, I can just say ‘confirm for 10,000’ and now it’s done. All I have to do is label and move on,” Marsha, an order handler at J. J. Keller said.

Speakeasy also considers the human element of the warehouse. It is multi-language and even recognizes accents, so your pickers can naturally do their job without having to repeat commands. It can even have some unexpected benefits. Ivanti customer TaylorMade found a reduced number of repetitive strain injuries after implementing Speakeasy.

So it’s easy to implement and train using existing hardware and systems, but what about actual results? Speakeasy helped J. J. Keller achieve a 10% gain in warehouse picking efficiency, doubling their goal in half the expected time. TaylorMade achieved a 49% reduction in error when picking after using Speakeasy. These results are just some of the examples of why 24 of the top 25 supply chains in the world use Ivanti products in their warehouse.

See if Speakeasy is right for you by requesting a custom demo of the solution.